Introduction

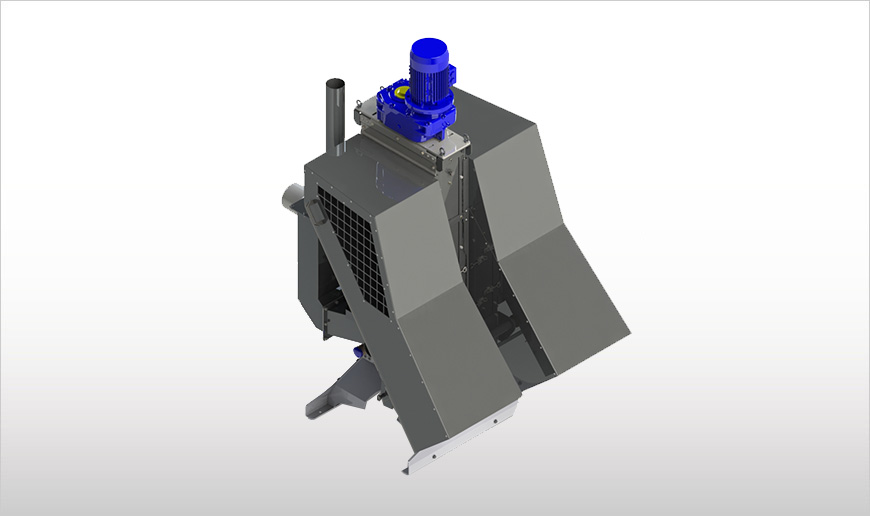

SEPCOM Vertical is an innovative screw press solids-liquid separator. Thanks to its special features, vertical work position and a twin-screw design, a variety of materials from biogas plants, industrial processes, as well as slurry from livestock breeding can be treated.

Due to the particular design of the SINT engineering polymer screws, various materials can be easily handled. The special shape of the screen chamber facilitates self-cleaning.

Self-cleaning SINT engineering polymer design

Technical Specs

Description

The SEPCOM 0150V is a screw press solids-liquid.

The machine consists of:

- an inlet module

- a separation and conveying module

- a compacting module

The feeding section is provided with a compensator tank and overflow outlet. It is designed to enable the material to directly flow into the separation module. The inlet is positioned at the bottom side of the machine.

The separation and conveying section consists of two vertical contra-rotating conveyor screws inside a screen, which lets the liquid phase pass while the conveyor screws lift the solid phase up into the compacting module.

The compacting module consists of a counter-pressure diaphragm that compacts the solid material, which is then discharged through two special chutes.

Function

SEPCOM Vertical is a solids-liquid separating machine including two vertical screws manufactured from SINT engineering polymer. The special design of the machine ensures that there is no clogging and no loss of the solids plug during operation. Performing separation by both gravity and mechanical compression, the machine is designed to separate the liquid phase from the solid phase of a wide range of materials such as sludge, sewage, manure, vegetable and fruit processing slurry and, in general, solids-liquid mixtures in which the percentage of liquid inside the solids may differ considerably. The separated solid phase and liquid phase can both be easily and cheaply handled.

Features

- Vertical access to screen facilitates maintenance

- Screws manufactured from SINT engineering polymer

- Self-adjusting counter-pressure diaphragm outlet (patented in various countries)

- Small footprint

- Up to 28% of dry matter

Benefits

- High performance wear-resistant screens

- Significant overall management cost reduction of solids-liquid separation of digestate from anaerobic digesters

- Significantly reduced assembly and maintenance time

- Affordable spare parts

Options

- Various types of outlet diaphragms

- 4 different SINT screw materials available

- Various screen sizes